DIY battery projects have gained popularity in recent years, thanks to the increasing demand for renewable energy sources and the need for sustainable living. These projects not only save money but also provide a valuable learning experience for enthusiasts. One crucial aspect of DIY battery projects is the need to connect individual cells together securely and efficiently. That's where DIY spotwelders come in. In this blog post, we'll explore the benefits of using DIY spotwelders, such as the Spot Welder Control Board from Amazon, and the essential tools required for your DIY battery projects.

The Importance of Spotwelding in DIY Battery Projects:

In any DIY battery project, whether it's building a custom power bank or assembling a battery pack for an electric vehicle, the process of connecting individual cells together plays a critical role. Spotwelding is the preferred method for connecting cells, as it ensures a strong and efficient electrical connection. Moreover, it minimizes the risk of damaging the delicate lithium-ion cells, which can be sensitive to heat generated by other welding methods.

Spot Welder Control Board: A Versatile and User-Friendly Solution:

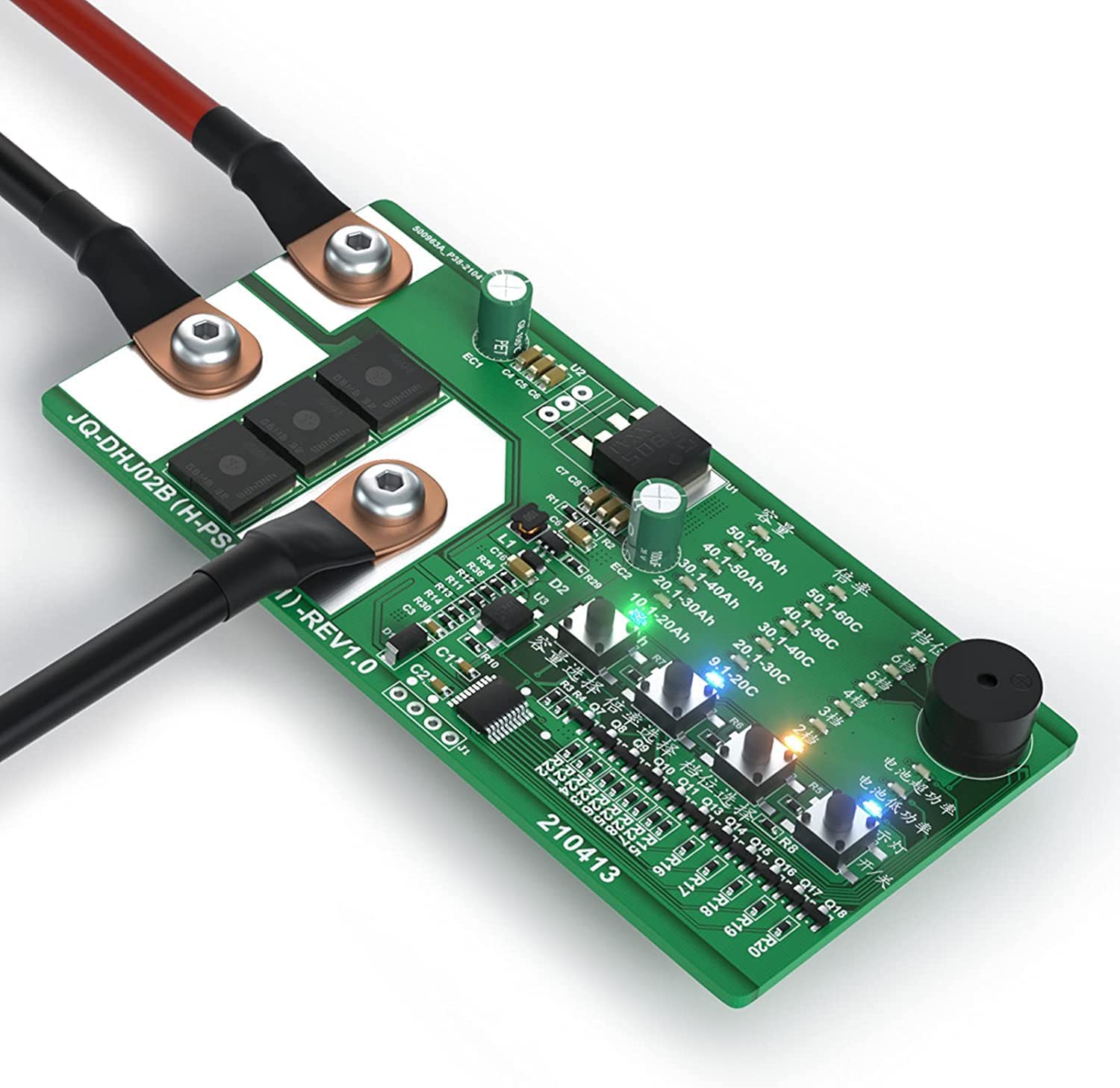

The Spot Welder Control Board is an excellent option for those looking to create their own DIY spotwelder. This 6-gear adjustable spot welding machine control board kit offers powerful functionality and safety features. With the ability to weld 0.3mm nickel sheets and support welding currents ranging from 100A to 900A, this control board is perfect for DIY battery projects.

Key Features:

-

Powerful Function: The Spot Welder Control Board can weld 0.3mm nickel sheets and offers six adjustable gears, supporting welding currents between 100A and 900A.

-

Safe and Intelligent: The control board intelligently matches and judges whether the power supply can work, preventing damage to the circuit board.

-

Wide Range of Applications: This spotwelder control board is suitable for welding 18650/26650/32650 cylindrical lithium batteries, nickel-hydrogen batteries, and nickel-cadmium batteries.

-

Power Selection: The control board requires a separate power supply, supporting 6.5V-16V power sources with a battery discharge current of <900A and a short circuit current of <1800A.

-

Easy to Use: The Spot Welder Control Board package includes a small file for maintaining the welding pen, the main board, and a full set of accessories. Users need only to provide battery power and connect the motherboard to DIY 18650 and other batteries.

Essential Tools for DIY Spotwelders with the Spot Welder Control Board:

The Spot Welder Control Board package simplifies the process of gathering essential tools for your DIY spotwelder. The kit includes several components that make it a one-stop solution for enthusiasts looking to build their own spotwelder:

-

Spotwelding Controller: The Spot Welder Control Board serves as the controller, managing the current flow and timing for the welding process. With support for welding currents between 100A and 900A, this control board is perfect for DIY battery projects.

-

Welding Pen Maintenance File: The package includes a small file for maintaining the welding pen. Regular maintenance ensures that the welding pen remains in good condition for optimal performance.

-

Spot Welder Main Board: The main board of the spot welder is included in the package, simplifying the assembly process.

-

Full Set of Accessories: The Spot Welder Control Board kit comes with a full set of accessories needed for building your spotwelder, reducing the need to source individual components separately.

-

Comprehensive Instructions: The product package provides detailed instructions and images on using the spot welder control board. This makes it easy for users to set up their DIY spotwelder, even if they have limited experience with electronics or engineering.

-

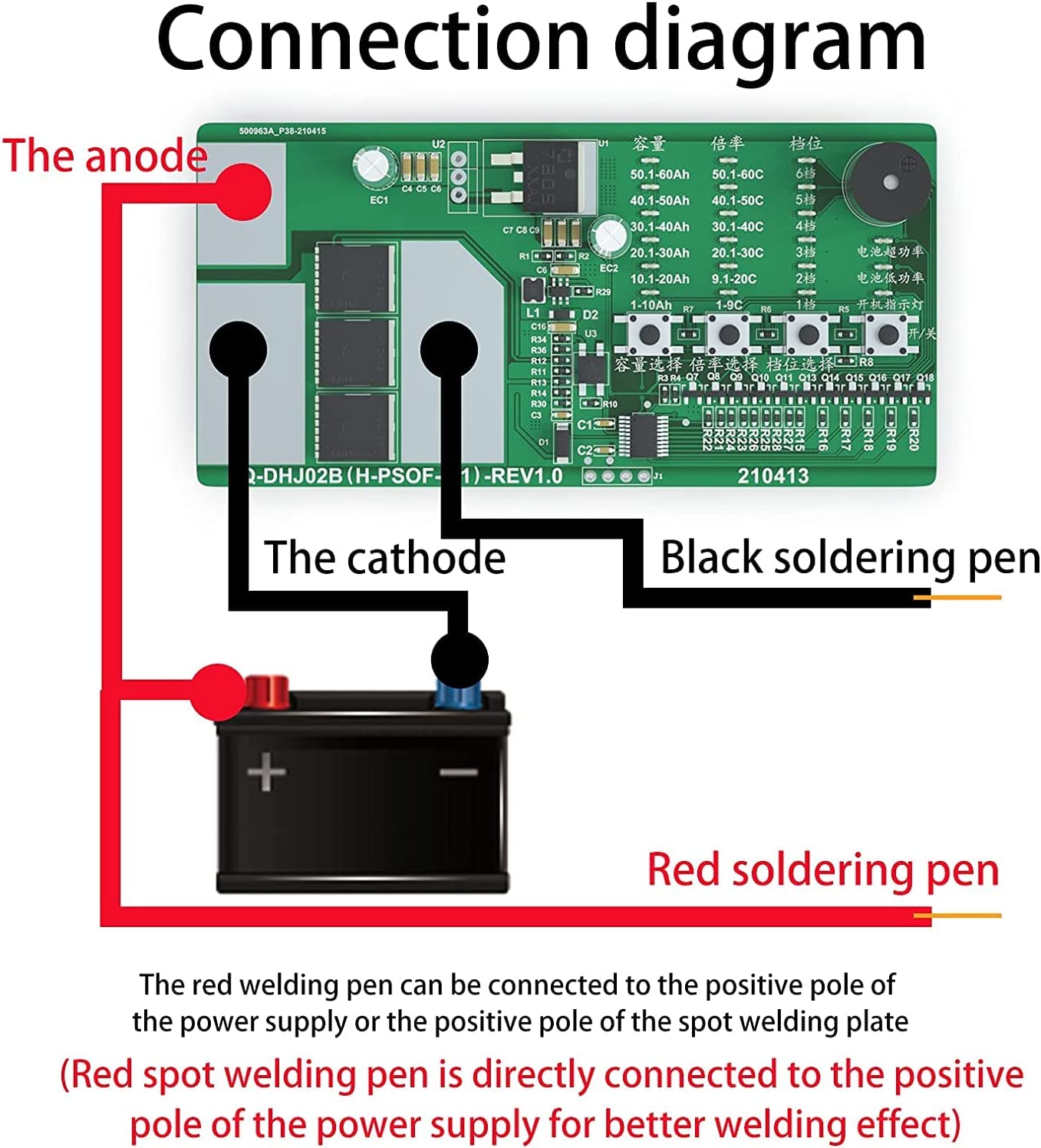

Power Supply: A car battery or similar power source is necessary to operate the spotwelder. The Spot Welder Control Board supports 6.5V-16V power supplies with a battery discharge current of <900A and a short circuit current of <1800A. Ensure that the chosen power supply falls within these specifications to avoid damaging the control board and ensure optimal performance.

Building Your DIY Spotwelder with the Spot Welder Control Board:

Once you have gathered all the necessary tools and components, including the Spot Welder Control Board, it's time to assemble your DIY spotwelder.

Follow the guidelines provided in the product package and images to connect the Spot Welder Control Board to your DIY battery setup. Remember to use a compatible power supply and adhere to the specified discharge and short circuit current limits to avoid damaging the control board.

Keep in mind that working with high-current electricity can be dangerous. Always exercise caution and follow safety guidelines when assembling and using your DIY spotwelder.

Conclusion:

A DIY spotwelder, such as the one built using the Spot Welder Control Board, is an essential tool for any DIY battery project, providing the ability to securely and efficiently connect cells together. With cost-effectiveness, customization, and the opportunity to learn valuable skills, building your own spotwelder is a rewarding experience. Make sure to gather all the essential tools and components, prioritize safety, and enjoy the process of creating your very own spotwelder for all your DIY battery projects.